Digital transformation is essential if automotive companies are going to continue to grow profitably.

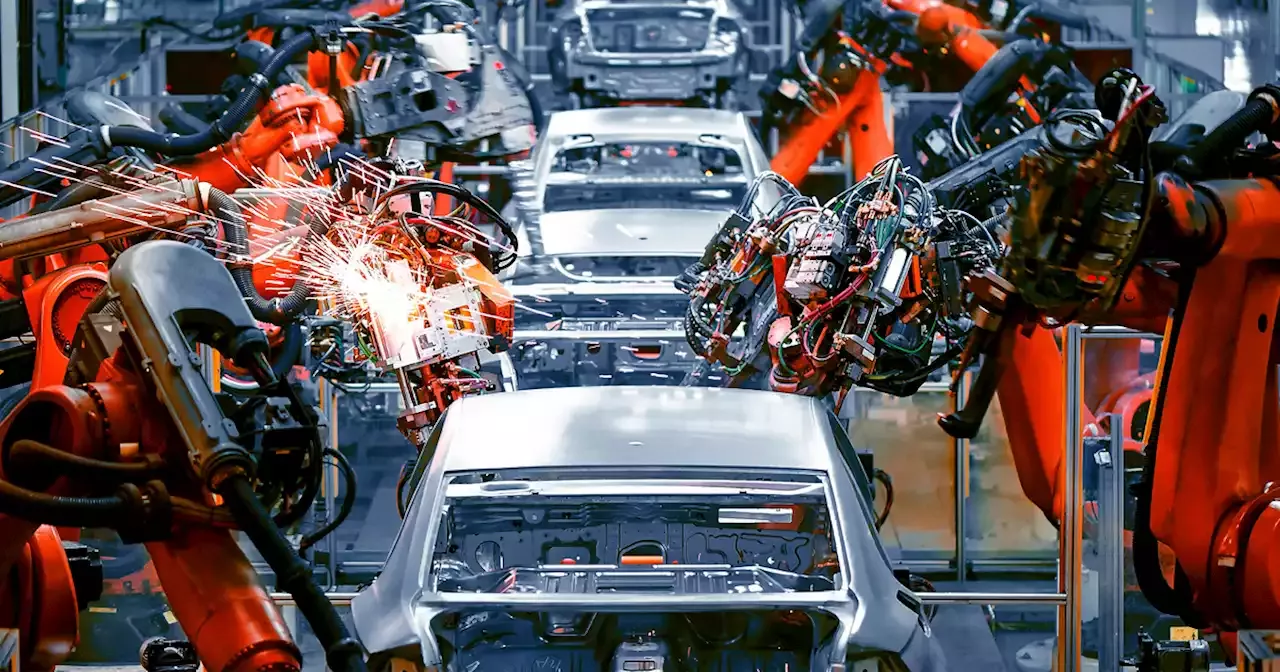

When digitally transformed companies connect all along the automotive supply chain, these benefits are magnified. Real-time data flows can be used to enable supply chain participants to more effectively manage procurement and inventory, optimize processes, and respond more quickly to customer or market changes. Predictive maintenance minimizes machine downtime, to keep parts and products moving.

One of the most significant challenges faced by traditional players in the automotive sector is technology debt. Many companies continue to rely on legacy systems that are decades old, using now-ancient software and hardware and technological duct tape to keep the business running. These companies typically manage the business on a plant-by-plant basis. Some might deploy MRP systems at one or more plants, but they struggle to scale up across the enterprise.